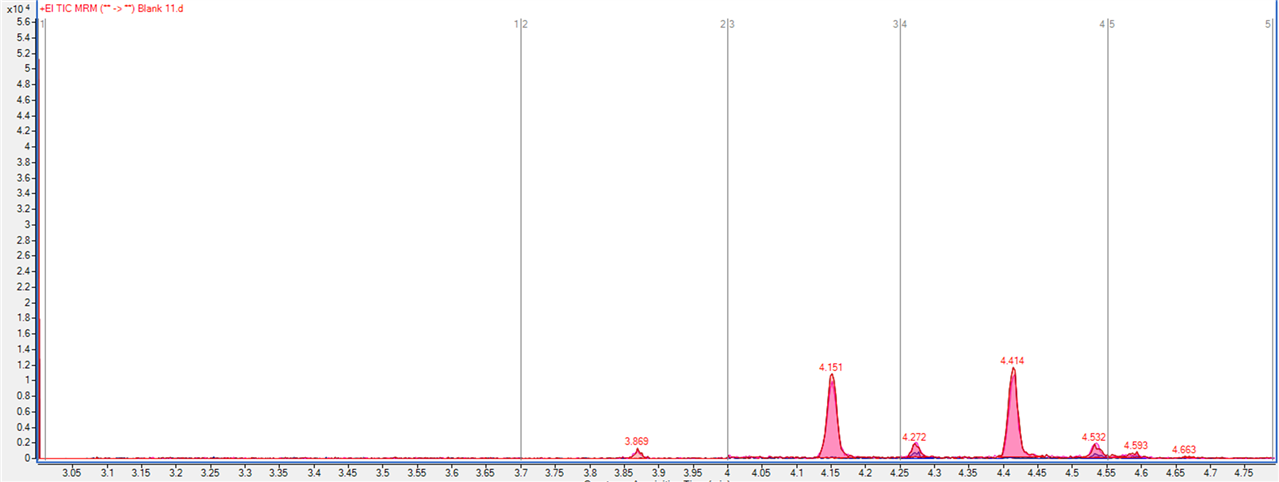

I'm seeing carry over contamination in my blanks after running SSTs.

The more blanks I run the bigger the peaks seem to get? I'm not sure what is going on. They're fresh blanks and this has only started after doing some general maintenance.

Including: - Source clean, quad clean, gold seal change, liner change, septum change.

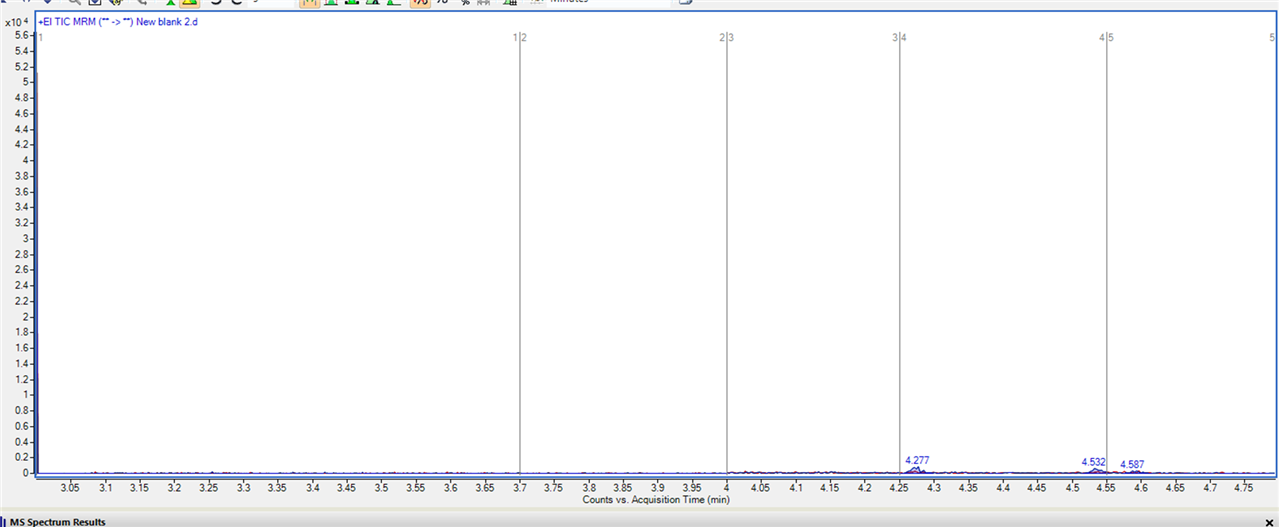

The first image is the blanks before the SST, and the second is the final blank after the SST.

Any advice welcome!