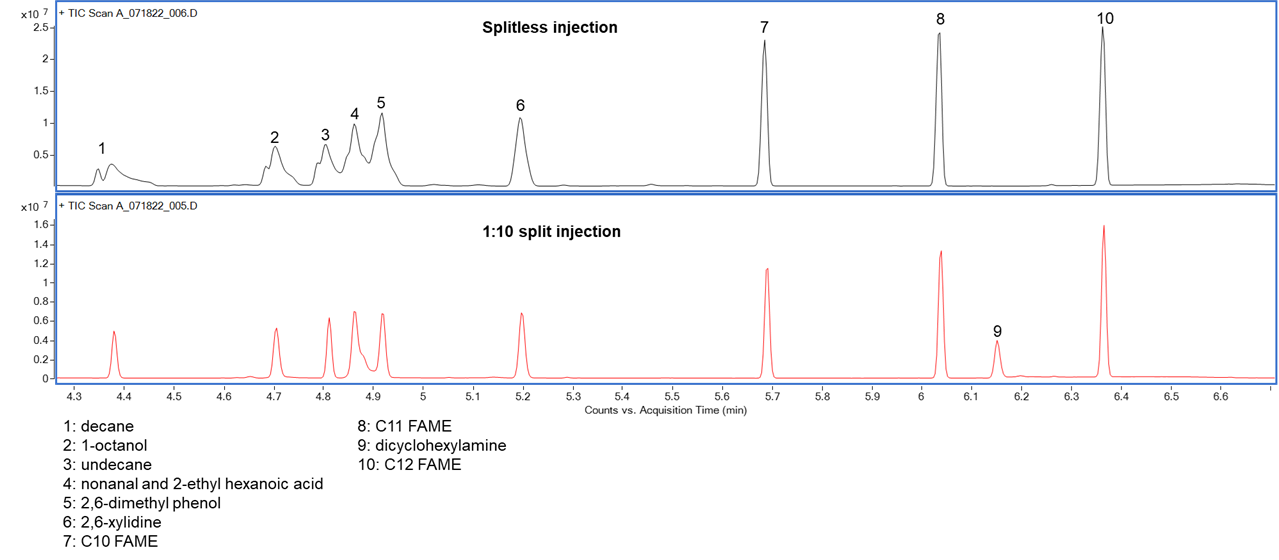

I installed and conditioned a new column (30m X 0.25 mm X 0.25 micron VF5ms + 10m EX guard; part # CP9013) at 320 °C for 30 mins and then ran repeated Grob injections. For the 10 split injections (A_071822_005), all compounds have a symmetrical, gaussian peak shape except for a couple of the compounds such as dicyclohexylamine and 2-ethyl hexanoic acid. For the splitless injection (A_071822_006), the earlier eluting peaks such as decane, 1-octanol, and undecane have split peaks but the later eluting peaks (C10 to C12 fatty acid methyl esters) all have symmetrical peaks.

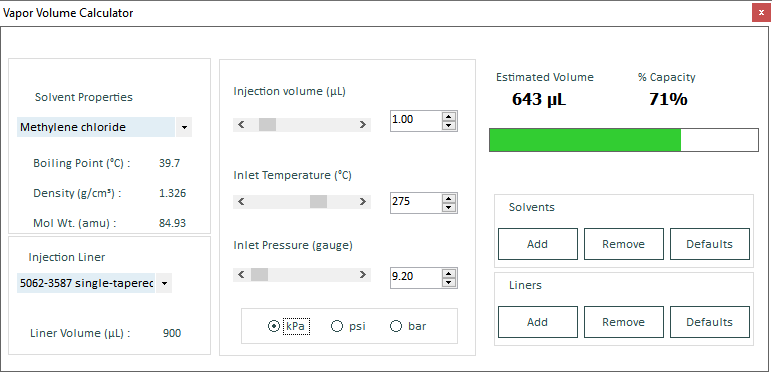

The temperature gradient for this run is 40 ° for 1 min, increase 40°C/min to 300 °C, hold for 4.5 mins. The inlet temperature is 275 °C and for the splitless injection, the purge flow to the split vent is 40 mL/min at 1 min. The injection volume is 1 microL. The Grob mix (Programmed Test Mix, Supelco, catalog # 47304) is diluted 10-fold into dichloromethane.

Why do the earlier eluting compounds have split peaks? Does it have anything to do with the EPC? Any suggestions are appreciated, thanks!