Hello Everyone,

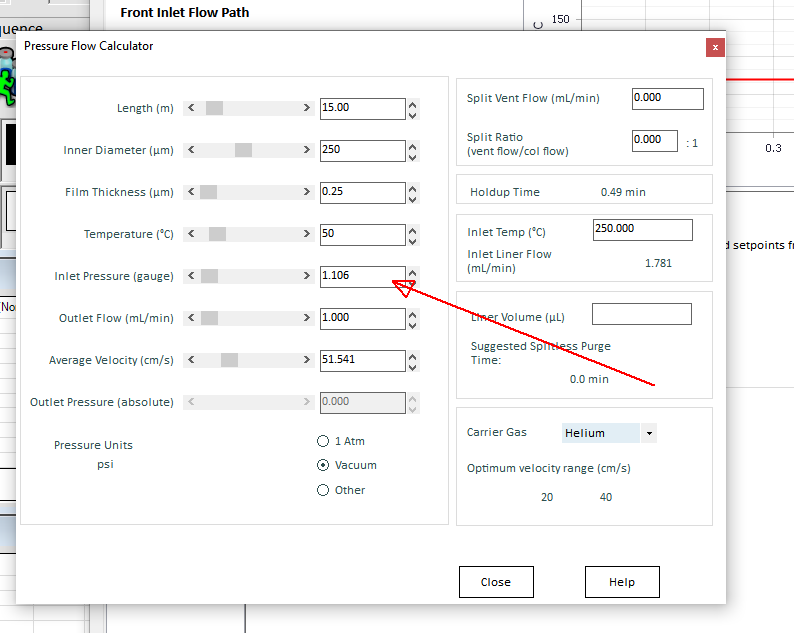

I am using a 15m 5HP column for 7820A GC - 5977B MS system. After sample run, I put the system in stand-by mode with the following parameters and found out 'front inlet pressure shutdown'.

1. front inlet temperature, MS quad, MS source - all at 100degC

2. oven temperature : 50degC

3. gas flow : 20mL/min

4. gas saver mode : on

5. mode : splitless

My question is :

1. what is the ideal pressure and gas flow to be maintained for a 15m column?

2. which is the correct mode - split/splitless/pulsed split/pulsed splitless for a 15m column?

Thanks!