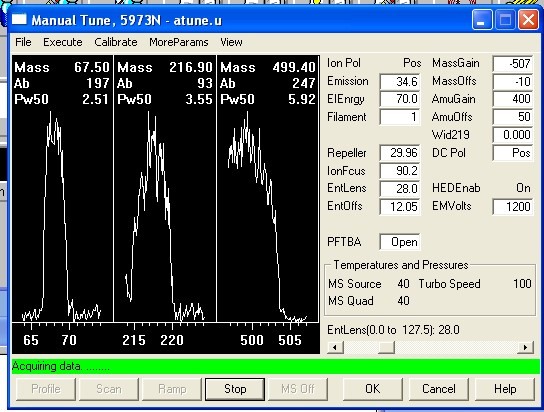

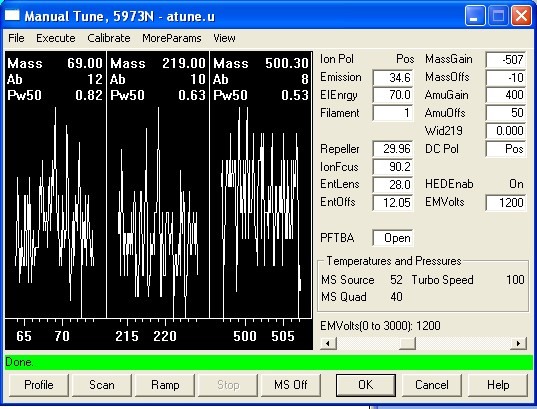

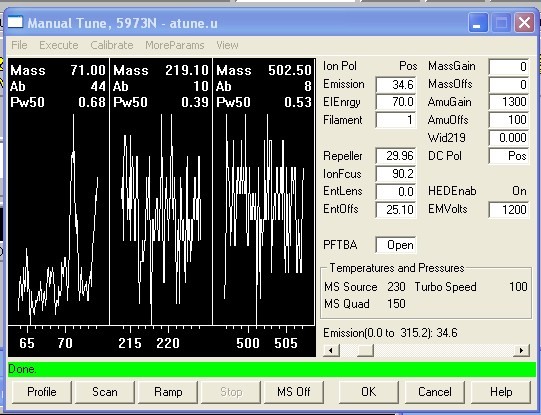

I recently have experienced an issue on not one, but TWO of our Agilent 5973 detectors that we have connected to GCs. The detector seems completely dead, if I run a sample I get a complete flatline. I can't do an autotune because it says "Tune action stopped: Cannot achieve constant peak widths". If I do a manual tune it looks like a lawn, maybe I see a little higher peak corresponding to the PFTBA standard ion peaks but overall it just looks like noise. Extremely few peaks, only 6 reported with an abundance of 962. This issue happened after I vented, turned off the GCMS, cut the column (we had a small leak), turned the GCMS back on, pumped down, and then tried to run a tune. The instrument was working perfectly fine, we just had a slight leak which was causing our peaks to look small (N2 abundance was 20%). Here are some of the things I've tried:

1) I tried re-cutting the column and making sure that it was only sticking out ~1-2mM into the analyzer.

2) Perhaps a corrupt tune file? I changed atune.u to atune.old and loaded a fresh copy of atune.u. No luck. I tried all the other tune files on our system, no luck.

3) We changed the filaments and cleaned the ion source very recently. Regardless, we tried another filament change and no luck. We haven't changed the EM Horn, could this be it? If so, how do we test for this?

4) I tried resetting the MSD by pressing the "menu" button until I saw the "controller" item. Then I pressed item and clicked reset controller. The MSD reset but no luck.

5) The PFTBA does look low but I was able to run a perfectly fine tune just minutes before I turned the system off to cut the column. I hear the solenoid click everytime I do a manual tune "profile" or "scan".

6) Vacuum & He flow look fine. I also did a few power cycles of everything. I checked and all cables are connected just fine.

I'm really at a loss and the leading theory is that the analyzer side board is broken and needs to be replaced. Is there a way I can verify this is the case? Furthermore, what are the chances that this breaks on two of our instruments just a few months apart? Am I doing something to damage the side board?

Below are some screenshots that help show the issue.

Thank you all so much