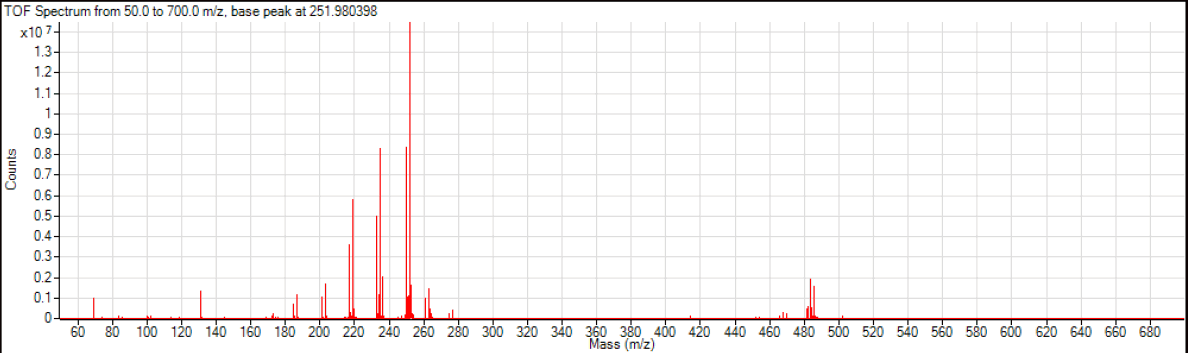

I have a huge contamination in my MS (GC-7200QTOF system). I see the peaks (251.9, 483.9) when turning on the filament and also during GC-runs (less with higher temperatures). My predecessor recalled seeing the same problem 6 years ago and that it was due to an oxidized filament. Changing filament and cleaning the source have helped back then.

So far I have changed liner and cutting parts of the column, this didn't help, backout of the source neither. Carrier gas can be excluded, the other GC-MS on the same gas supply don't have that contamination. We have an oil-free foreline pump.

Can someone confirm that this is the filament? How can this be prevented from happening again?