Why is the purge flow affecting the column flow, e.g. we set purge flow to 0.5 mL/min, and that leads to the column flow of 1.4 mL/min not being reached.

Why is the purge flow affecting the column flow, e.g. we set purge flow to 0.5 mL/min, and that leads to the column flow of 1.4 mL/min not being reached.

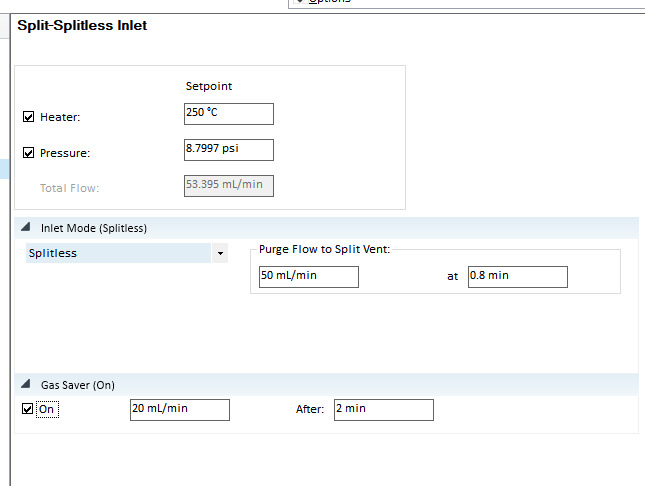

Liquid injection Splitless mode changes things in the inlet over time. You want it to look like the example below.

During the time from injection to 0.8 minutes, the split vent flow is off/diverted (depending on the instrument) and all flow goes through the liner onto the column. At 0.8 minutes, that flow changes to 50 ml/min to sweep any sample or solvent residue out of the liner. Then at 2 minutes, the Gas Saver mode reduces the 50 ml/min to 20 ml/min, the minimum total flow that the SSL/MMI inlet requires to operate properly.

The 0.8 minutes depends on your column flow, inlet liner volume, inlet temperature, and solvent injected. The easy way to choose is to think about how long your column flow takes to sweep the inlet liner volume. You say you are using 1.4 ml/min column flow (a bit high for the ion source, not bad, but high), and the liner volume of most Splitless liners is about 800uL, so 0.8/1.4 = 0.57 minutes. I would pad that time by at least 0.1 minutes but not all that much more and use 0.7 minutes.

Make sure and read the Operations Manuals. You can also view a variety of documents, webinars, and videos on Agilent.com.