Hello,

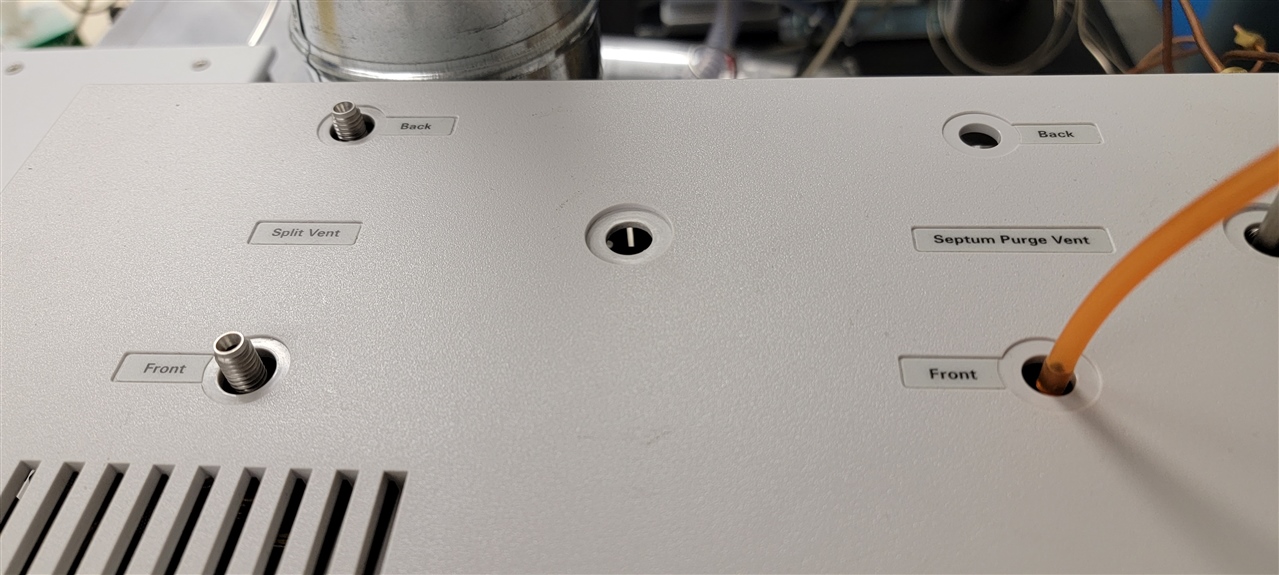

Our lab is looking at directing potential airborne contaminants coming from a GC towards an exhaust vent. The three possible locations I could locate are the split vent, septum purge vent and vacuum pump. Between the split vent and septum purge vent, which one theoretically has the potential to release more harmful substances into the air? What is the difference between the both? Why do some instruments have a back and front septum purge vent while others only have a front (I think this is because the back is using a VI inlet?) Would it cause issues if tubing is placed on top of the events as seen in the picture?