Can any one confirm that when valve actuate in GC, that time atmospheric pressure change..if yes then how to correct so that same pressure will be there after n before actuation of valve..

Can any one confirm that when valve actuate in GC, that time atmospheric pressure change..if yes then how to correct so that same pressure will be there after n before actuation of valve..

Please provide us a precise meaning of "atmospheric pressure". Do you mean air supply pressure? If yes, you just need to increase air pressure through gas regulator on top of gas tank. You can increase it to almost 5 Bar but this can increase the sound of actuation more loudly !

If you mean of atmospheric pressure something rather than air pressure, please share with us your valve diagram (like picture I send). I suppose you probably have a NGA with one 10 port and two 6 port valves. So please tell us more about your pressure problem and valve diagram.

Please provide us a precise meaning of "atmospheric pressure". Do you mean air supply pressure? If yes, you just need to increase air pressure through gas regulator on top of gas tank. You can increase it to almost 5 Bar but this can increase the sound of actuation more loudly !

If you mean of atmospheric pressure something rather than air pressure, please share with us your valve diagram (like picture I send). I suppose you probably have a NGA with one 10 port and two 6 port valves. So please tell us more about your pressure problem and valve diagram.

Thanks for reply..See, valving system sitting on top of GC..Valves are inside valve box and actuators are on top of valve box..When valve goes on or off position due to actuation that time flow/pressure changes for short period..So i am asking how we can keep it at constant...This thing you can observe with external flow or pressure meter..GC is not going to give any error..

"flow/pressure changes" is happening for which gas? Where do you attache the flow or pressure meter?

Your system likely came with a valve diagram, if you can please post an image of it.

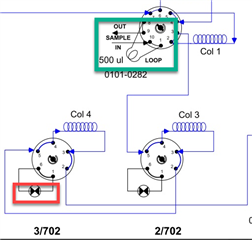

Using H.Ahmadpour's valve diagram as an example, I've boxed two areas that might be related to your posts. The green box is where sample introduction is performed and loading the sample loop in a consistent way is important. However based off your last reply, it seems like your problem is not the sample loop but actually one of the other valves, in my example below I boxed in red a restrictor for one of the valves with Col 4. The purpose of the restrictor is to balance out any pressure/flow change from when the valve actuates. Col 4 has column dimensions that cause a certain amount of restriction on the pressure/flow of the system. The idea of the restrictor on the same valve is to dial the restrictor until the restrictor is providing the same amount of restriction as Col. 4 for that valve. Then when the valve articulates there is no large change of flow/pressure for the system.

The image at the bottom of the post shows what the restrictor looks like on the GC valve box. It has a slotted head for a screwdriver to make adjustments.

Hi,

When activating a valve for gas sampling injection in On/Off position, the sample loop is either connected or removed from being in series with the carrier gas. The carrier gas pressure will change/drop for a very short period. This is normal observations.

A quick GSV activation will result in almost not notable pressure drops. If using a packed column the pressure drop is more notable compared with use of capillary columns.

Best regards -

Lars