Hello!

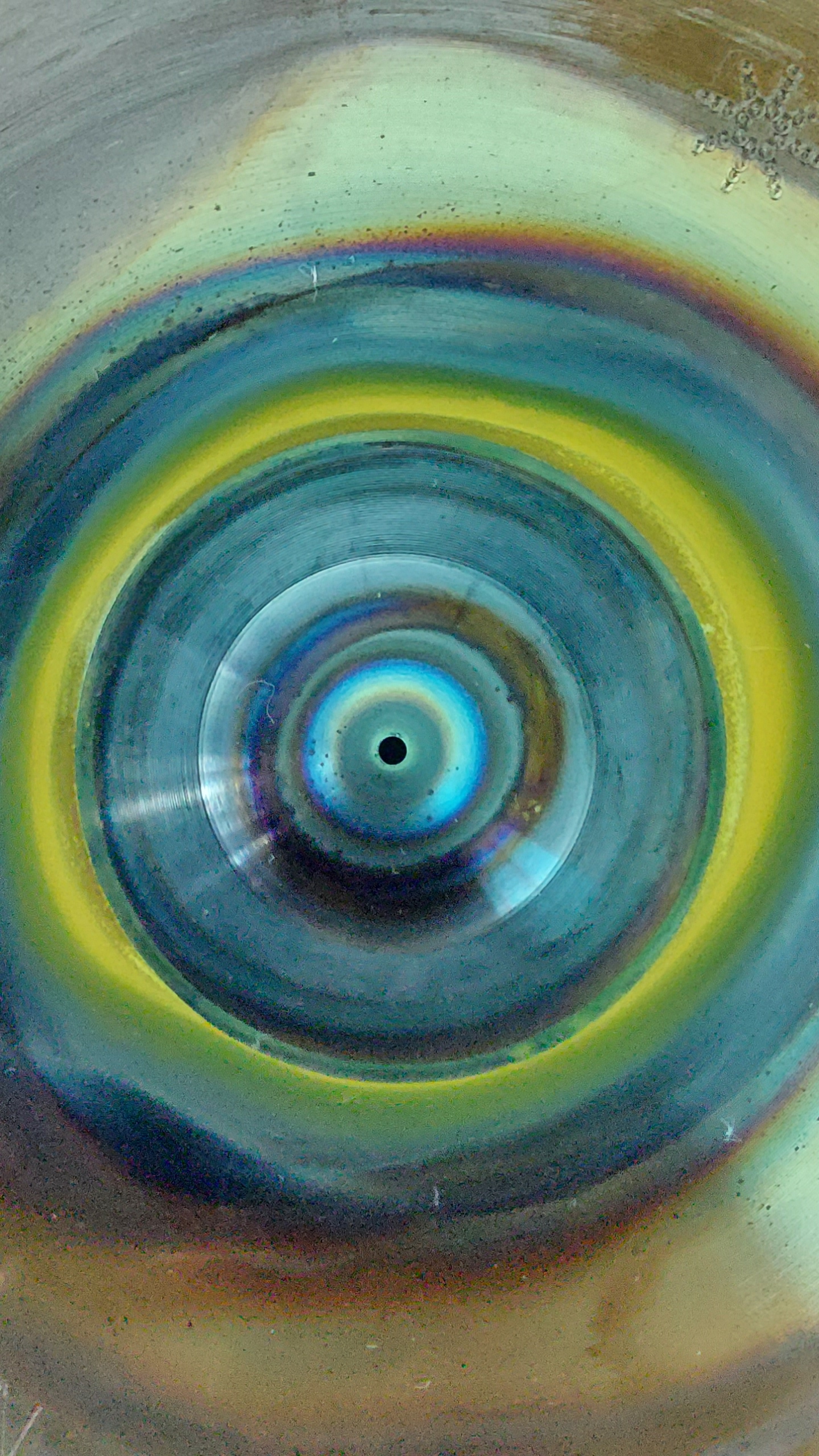

The problems emerged after cone cleaning (Ni sampler with Cu base and Ni skimmer). We cleaned them with wet cotton swab and sonicated in pure water about 5 minutes in different beakers. Because the Citranox solution is not available for us right now, for the next step we cleaned cones with 2% HNO3 and sonicated again for 3 minutes, as Hardware Maintenance Manual recommended.

After this a high signal of Cu occurred in all measured solutions. With time the signal decreased. However, after more than three hours of measurements the signal didn`t drop to previously registered background levels and comprised 173 cps (He mode, general purpose plasma).

Th second problem was that we obtained high Oxide ratio, and it continued to increase (3%, 8% and 20%).

Please, give us some advice.

Thank you in advance!